Get 2-inch printing fit to your work with endurance to handle everyday hazards.

2020 was already projected to be the year of explosive data center growth due to emerging 5G, IoT and IIoT technologies. Now several reports show that the recent COVID-19 pandemic has increased global Internet traffic with VPN usage and online gaming and video streaming levels reaching an all-time high. From on-premises to colocations to the cloud, data centers of all sizes across all vertical markets are ramping up capacity to handle more data-intensive, business-critical applications and mobile computing than ever before. At the same time, data center architecture is advancing towards a model of provisioning and accessing data over fabrics with more redundancy, virtualization and hybrid solutions. These trends have significantly increased the complexity and density of intra-data-center links and are presenting significant management challenges.

Proper labeling per the TIA-606-C administration standard now plays a bigger role than ever in managing today’s complex data centers. Not only does following cable labeling standards and best practices project professionalism, it also lets data center managers and operators keep track of assets, streamline workflows, and improve accuracy and efficiency of moves, adds and changes.

But to really save time and money with labeling, you need the right tool for the job. While consumer-grade office labelers are great for putting your name on your calculator or easily locating the right file drawer, when it comes to the data center, they are simply not up to the task. Only industrial professional-grade labelers designed specifically for datacom can stand up to the rigors of the data center while bringing maximum efficiency to the labeling process that is essential during this time of unprecedented data center growth.

Handheld help to the rescue

Gone are the days of arriving at the job site with pages of peel-off labels that often get lost or damaged and require time-consuming hunting and pecking, only to find that the label you need is missing or inaccurate. Today’s data centers are far too large and complex for such inefficient practices. When it comes to labeling hundreds or even thousands of data center connections, as well as cables, pathways, active equipment, racks and cabinets, and bonding and grounding elements, the advantage of having a portable handheld industrial labeler means you can print the data center labels you need when you need them – whether you’re standing in front of a rack or up on ladder labeling cables or pathways.

With its built-in Wi-Fi and professional labeling functions designed specifically for datacom installations, Brother’s handheld PT-E550W industrial label printer does the work for you by easily downloading existing label data from your smartphone, tablet or laptop so all your labels are right at your fingertips for fast, easy printing. And using the quick applications keys, you can easily tell the PT-E550W what type of label you need to print—general, faceplate, cable wrap, cable flag, patch panel or punch block.

Not only does the PT-E550W allow you to easily locate specific labels and get to the functions you need, but its serialization feature is sure to help save you time. Most equipment and patch panels have either 24 or 48 ports, and our serialization feature lets you tell the PT-E550W a range and number of labels to automatically print for a group of ports. And with an industry-leading print speed of up to 30mm per second and the ability to create half-cut, easy-peel labels, you can quickly print out an entire series of labels on one strip.

There’s an app for that!

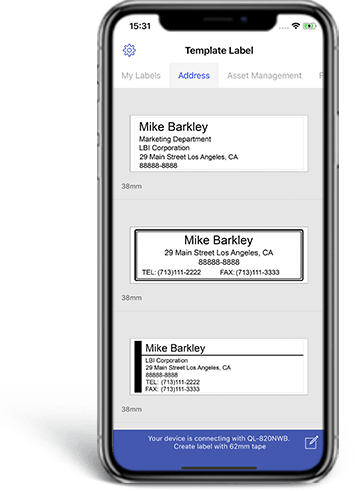

While being able to download spreadsheets of identifiers into a handheld labeler like the PT-E550W can help ensure accuracy, there’s still that chance that something changes in the field or a certain component got left off the list. Available for iOS and Android™ devices, Brother’s iPrint&Label mobile app lets you create customizable templates and labels right on your smartphone, tablet or laptop and wirelessly print them from the PT-E550W. The app lets you choose the label size and format, add text in whatever font type or size you prefer, add images and choose from hundreds of industrial symbols. And because you can save your designs, you can use them over and over again to save time and ensure consistency.

With more data center links and components than ever before, keeping track of assets is also easy with the asset management feature in the iPrint&Label app.

Ideal for inventory control and data center infrastructure management, simply add barcodes or QR codes to your labels that can be scanned to bring up specific device specs, end-to-end circuit traces, pathway mapping or a list of active or passive components in a specific rack or cabinet. These codes might just help you later identify where you can effectively add more data center capacity.

When it comes to deploying data center infrastructure, the typical steps are design, install, test and label. Testing is required for compliance (and often vendor warranty), and if you’re using a Fluke Networks’ Versiv™ tester model and taking advantage of their cloud-based LinkWare™ Live service, labeling can be even easier and more accurate. That’s because Brother’s iLink&Label mobile app allows you to download identifiers directly from LinkWare Live and wirelessly send them to the handheld PT-E550W for printing. Together, LinkWare Live and iLink&Label bridge the gap between the office where the project originates and the jobsite, ensuring that the same data is used for both testing and labeling. Not only does this improve consistency and accuracy, but you can easily call up test results based on your labels to help you quickly and easily identify if a particular link has the headroom to support more bandwidth.

In all tapes and sizes

Any discussion on labeling for data centers wouldn’t be complete without mentioning the actual tape you’re going to print on. In other words, if you think tape doesn’t matter, think again.

The tape that you use to label a data center must be able to stand the test of time. That means the adhesive must be strong enough so that it doesn’t peel off, the text must resist smudging or fading and the material itself must be durable enough to stand up to abrasions and other environmental elements. Brother’s preloaded drop-in tape cartridges for use with the PT-E550W feature a built-in laminating film that is applied over the label during the printing process, so your final labels emerge automatically laminated and protected.

And because labels aren’t one size fits all, Brother laminated tapes come in various adhesive strengths for ensuring a better bond on any surface, from smooth and flat to plastic, textured and powder-coated. They also come in a wide range of colors, which is ideal for complying with most of the latest TIA-606-C recommended color labeling schemes.

Brother also has a variety of application-specific options like FlexID tape that is ideal for cable wraps, narrow tape for effectively labeling high-density patching panels, tamper-indicating labels for high-security mission critical environments and heat-shrinkable tube labels.

No more excuses!

While there is still evidence that some data center deployments are not properly labeled per TIA-606-C standards, or worse not labeled at all, with the ease of a handheld label printer like the PT-E550W, there’s simply no excuse for not labeling.

Besides, labeling and maintaining good records will help save you time and money in the long run. Today’s data center managers in the midst of expansions and moves, adds and changes will know what’s deployed where and what it connects to, reducing the chance of accidental disconnects and ultimately making it easier to reconfigure and add capacity when and where it’s needed.