Episode 32: Why Labeling Should Be Part of Your Building Specs

Hey contractors and subs! Hear from Todd on the importance of labeling specifications for your new builds.

Get the job done right. NEW P-touch EDGE does the heavy lifting for you.

The construction industry remains robust across the United States, with new construction providing expanded opportunities for building capabilities and technology innovations. Often called connected buildings, these new or smart buildings offer the potential for increased energy efficiency, user well-being and overall productivity.

With the construction of new buildings, there also comes new challenges related to more complex operating systems. These systems include heating and cooling, lighting, access control, security, electrical components, network connectivity, and even infotainment systems that interact with occupants. When any one of these systems goes down, contractors need to quickly repair or fix an issue. This also means that more contractors and technicians are accessing systems than ever before. Because of these complex systems, including labeling guidance in a building’s specifications has become a must.

A building’s plans and specifications are must-have tools for communicating what should be built and how to build it to everyone on the building team. The plans and written specifications must work together – with the plans detailing what to build, and the specifications highlighting how to build it. Since every structure is unique, specifications define the requirements for products, materials, and workmanship upon which the contract is based, as well as the requirements from administration and performance of the project.

With so much going into a building’s specifications, a label can be an afterthought. However, with some upfront planning, labeling plays a key role in a building’s specification plan. By considering all the aspects of a system that could benefit from a label and the specifications of exactly what should be labeled, contractors can help facilitate fast, seamless troubleshooting and repairs in the future. Specifications should be as specific as possible, highlight the printer equipment, and even labeling tape that will adequately complete the job and withstand the environment for years to come. Without details, the right equipment may not be selected. Existing buildings that are also undergoing renovations or updates should add labels to building specification plans for new systems as well.

Get our free labeling specifications template

Labels are an important component of a building’s maintenance and provide many positive benefits. For example, when labels are added to a specification plan and applied in a building, the technician’s job becomes easier. They can walk up to a cable or wire and see the label right away. If there is no label, that can lead to a number of challenges and time-consuming problems and even create a safety concern. If a contractor disconnects the wrong wire/cable or doesn’t know which part of the infrastructure supports a specific system, it can be a big liability. This can include bringing down critical building systems or other big consequences.

By specifically calling out the necessary labels (and printers needed to create them), contractors know which labels to produce and which products are best for labeling. Including the product name or label type in the specifications means that the purchasing or facilities manager knows exactly what to purchase and makes purchasing very easy. The more time spent detailing each step of the labeling in a specification plan, including the label tape, the more likely a vision for the project will be executed accurately and the less chance for unplanned repair difficulties.

When selecting label tapes and printer hardware, consider tools that are durable and easy to use. The most effective tools allow technicians to get labeling completed quickly, accurately, and with little added hassle. For example, look for hardware with a half-cut feature that doesn’t leave little backing pieces everywhere, which creates extra clean-up that means extra time on the clock. A single long strip is easier to clean up and will get the job complete faster. Here are a few other areas to consider when selecting labeling tools:

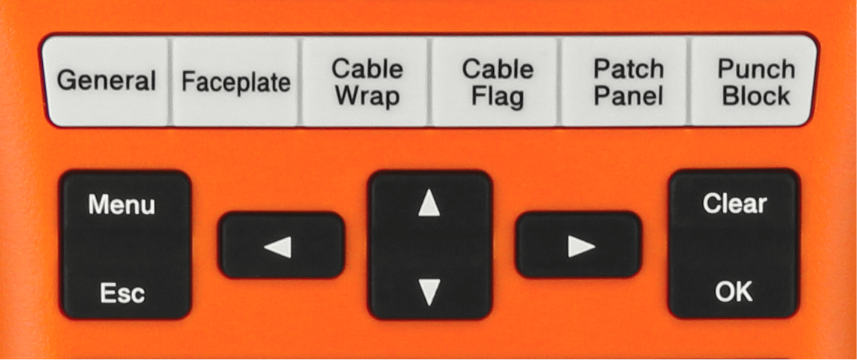

Consider labeling tools that are remarkably easy to use, with intuitive menus and built-in label application keys. Create and produce professional labels in seconds, without ever reading a manual.

Smart keys for common label types, built-in templates and symbols, and advanced connectivity options. Accurately label even the largest jobs – and simplify future changes.

Durable laminated labels that remain affixed and clearly readable for years. Resistant to abrasion, harsh UV exposure, extreme heat or cold, grease, water, grit, grime and industrial solvents. Must be able to handle more frequent cleaning and harsher chemicals.

Navigating the world of label printers and tools is complex. Getting labels integrated into your project’s specifications is even more complex. But organizations don’t need to find the best solutions or create specifications alone. Our team of experts are available to understand your challenges and can provide input, training, and the solutions needed to create a smooth labeling process. Labeling can help save time and money in the long run. Ensure it is done correctly the first time and it has lasting durability.

Hey contractors and subs! Hear from Todd on the importance of labeling specifications for your new builds.